Let’s face it: sourcing custom textile accessories from overseas can feel like a gamble.

You approve a beautiful sample on screen — but when bulk goods arrive, the reality can be disappointing: dull colors, flimsy fabric, or missed deadlines that ruin an entire launch.

Table of Contents

ToggleExploring the Elegance of Custom Silk Scarves

If you have sourced scarves or bandanas from China before, you probably already know this pain.

As a brand manager or professional buyer, you don’t just need a supplier — you need a manufacturing partner who understands quality consistency, cost transparency, and long-term supply chain reliability.

At Bysporting, we are not traders or middlemen.

We are an industrial–trade integrated factory, with 8 years of manufacturing experience and over USD 7 million (50M RMB) in annual sales. We handle production in-house, from fabric sourcing to printing, hemming, and final QC.

We have seen nearly every shortcut and hidden risk in this industry.

Today, we are opening the “black box” of manufacturing to help you source Custom Silk Scarves and Seamless Bandanas and Silk Scarves like a professional buyer, ensuring that your experience with sourcing Silk Scarves meets your expectations.

Part 1: 3 Costly Mistakes to Avoid When Sourcing Custom Scarves

Before placing your next PO (Purchase Order), check whether you may be facing these common — and expensive — sourcing traps.

Mistake 1: Falling for the “Material Trap” (Silk vs. Polyester)

Material ambiguity is one of the biggest issues in the scarf industry.

Some suppliers label high-quality polyester as “Silk Satin”, “Ice Silk”, or “Silky Fabric”, without clearly disclosing that it is synthetic. While premium polyester can be durable and cost-effective, it is not Mulberry Silk — and the difference matters to your brand positioning.

✅ The Bysporting Standard: Radical Transparency

- 100% Mulberry Silk

We clearly specify the silk grade (6A) and exact Momme weight in writing. - Premium Polyester / Microfiber

Clearly labeled and recommended only for performance-driven use cases, such as outdoor bandanas or UV-protection neck gaiters.

Proof matters.

We actively support third-party testing and can provide SGS certification reports for our fabric batches, ensuring compliance with US and EU environmental standards.

Mistake 2: The “Color Nightmare” (Poor Backside Penetration)

Have you ever received a scarf that looks vibrant on the front, but almost white or washed-out on the back?

This is a classic sign of poor ink penetration during digital printing. It instantly lowers perceived quality and makes even premium designs look inexpensive.

✅ Our Solution: Advanced Printing Control

- For Silk Scarves

We use advanced double-sided digital printing combined with reactive inks, achieving 80–90% backside color penetration. - For Custom Bandanas

We apply high-quality sublimation printing, allowing the ink to bond with the fiber — ensuring color stability even after 100+ washes.

The result is consistent color performance that meets retail and brand expectations.

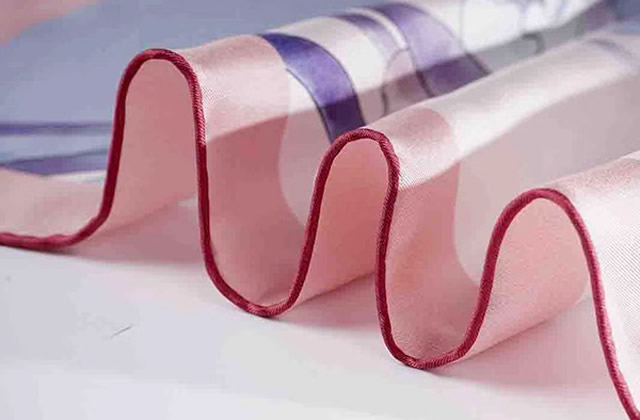

Mistake 3: Underestimating “Hemming” Quality

The edge finish of a scarf often determines its true market positioning.

A machine-stitched “baby hem” immediately signals a budget item, while a hand-rolled hem is widely recognized by buyers as a mark of luxury craftsmanship.

✅ Our Craftsmanship Commitment

Our hand-rolled hems are completed by skilled artisans.

Each worker spends nearly an hour finishing just a small batch, creating a plump, invisible stitch that luxury buyers and museum shops expect.

Macro comparison — machine-rolled hem vs. Bysporting hand-rolled hem]

Part 2: Behind the Price Tag — Understanding the Cost Breakdown

Why does one factory quote USD 5.00 while another quotes USD 8.00 for what appears to be the same scarf?

At Bysporting, we believe buyers deserve clarity — not surprises.

1. Raw Material: The “Momme” Factor

In silk production, Momme (mm) measures fabric weight and thickness.

- 12mm: Lightweight, slightly translucent, budget-oriented

- 14mm: Industry standard for most fashion and retail brands

- 16mm+: Luxury grade with heavier drape and opacity

Buyer Insight:

Quotes that seem “too good to be true” often involve silently switching from 14mm to 12mm. We never change Momme weight without written confirmation.

2. Printing & Ink Safety

Low-cost inks fade quickly and may contain restricted substances.

We use eco-certified inks that comply with REACH (EU) and Proposition 65 (California) regulations. While this slightly increases cost, it protects your brand from legal risks and customer complaints.

3. Labor & Quality Control

Hand-rolled hems and strict QC standards require skilled labor.

We pay fair wages to retain experienced workers, allowing us to maintain a defect rate below 0.2% — a critical factor for brands that value consistency over one-time savings.

Part 3: From Concept to Reality — Our OEM / ODM Process

You don’t need to be a textile expert to launch a custom scarf line.

Our OEM/ODM service is designed to simplify the entire process.

Step 1: Design Consultation

Send us your artwork (AI / PSD). Our in-house design team checks resolution, layout, and color suitability based on scarf shape (square or oblong).

Step 2: Rapid Prototyping (3–7 Days)

Because production is handled in-house, we can deliver physical samples within 3–7 days.

Step 3: AQL 2.5 Quality Control

Every order goes through a 3-step inspection:

- Fabric inspection before printing

- Print clarity and color accuracy check

- Final hemming and packaging inspection

Part 4: Case Study — Helping a Museum Shop Create a Best-Seller

The Client: A renowned European art museum shop

The Challenge: Reproducing a famous oil painting on a scarf with high color accuracy — within a controlled budget

Bysporting’s Solution:

- Material Selection

14mm silk satin was recommended for its glossy surface and cost-efficiency. - Color Tuning

Our engineers adjusted the ICC color profile to preserve the painting’s original texture and depth. - Packaging Optimization

A custom envelope package with the museum’s logo added perceived value without increasing shipping volume.

The Result:

500 units sold out within 2 weeks.

The client has continued quarterly reorders for over 3 years.

Ready to Upgrade Your Supply Chain?

Sourcing custom scarves shouldn’t feel risky.

With the right factory partner, it becomes one of the most predictable parts of your business.

Whether you need Custom Printed Bandanas for events or High-End Silk Scarves for boutiques, Bysporting offers real factory capabilities combined with trade expertise.

🚀 Take the Next Step

Don’t guess your costs. Contact us for a Free Cost Analysis and a Digital Mockup within 24 hours.

Visit us at: https://bysporting.com/

Your Trusted Manufacturing Partner for Outdoor & Fashion Accessories