導入

Let’s be real: Silk is gorgeous, but it can be a total nightmare to work with. It slips, it slides, and if you look at it the wrong way, it frays.

If you’ve been Googling how to make a silk scarf or how to sew a シルクスカーフ, you’ve probably seen plenty of tutorials using standard sewing machines. But here is the insider truth: at our factory, where we have been manufacturing scarves for over 8 years, we know that the difference between a “craft project” and a “luxury item” comes down to one thing—the edge.

Whether you are a DIY enthusiast wanting to make a gift, or a designer looking to launch a custom made scarf line, this guide will walk you through the real process—from cutting the slippery fabric to achieving those coveted hand-rolled edges.

Step 1: Picking the Right Fabric (Don’t Start with Satin)

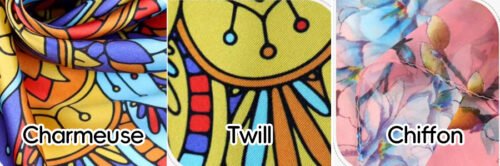

Before you even touch a pair of scissors, you need to nail the silk material for scarves. Rookie mistake: starting with Chiffon or Satin Charmeuse. They are incredibly slippery and frustrating for beginners.

- Our Factory Recommendation: Go for 14mm or 16mm Silk Twill. It has a bit of texture (“grain”) which gives it grip, making it much easier to cut and sew straight.

- The “Tissue Paper” Hack: Silk moves when you cut it. A pro tip we use? Layer a piece of tissue paper underneath the silk and cut through both layers. This stabilizes the fabric and ensures your square silk scarves are actually square, not diamond-shaped.

Step 2: The Hem — DIY vs. Designer Quality

This is the make-or-break moment. According to search trends, a lot of you are asking how to hem a scarf by hand. Here is the breakdown of the two main methods:

Method A: The Machine Rolled Hem (DIY Friendly)

If you just want to get it done, use the “rolled hem foot” on your sewing machine.

- Set your stitch length to 2mm.

- Feed the raw edge into the spiral of the foot.

- The Result: This creates what we call a “baby hem”. It’s flat and stitched down. It’s fine for everyday wear, but it lacks that expensive, 3D look.

Method B: The French Hand-Rolled Hem (The Luxury Standard)

This is what brands like Hermès do. It is also our factory’s specialty.

- The Prep: You need a super fine needle and silk thread.

- The Technique: You don’t just fold the edge; you use wet fingers (seriously) to roll the edge into a tight, round cylinder. Then, you use an invisible stitch to catch just a tiny thread of the fabric.

- The Effort: It takes one of our skilled artisans about 45 minutes to finish one 90cm scarf.

- The Result: A plump, rounded edge that screams luxury silk scarf.

Step 3: Styling Hack (No Sewing Required)

Maybe you already have a beautiful piece of silk fabric and you aren’t ready to sew. A popular search right now is how to make silk scarf into top.

Here is the easiest “no-sew” hack:

- The Halter Top: Fold a large square scarf (90cm+) into a triangle. Take the two top corners and tie them behind your neck. Take the bottom two corners and knot them behind your back.

- Boom—you have a custom silk top without a single stitch.

Step 4: Troubleshooting Fraying

Silk loves to unravel. A common question we get is how to stop a silk scarf from fraying.

- The Quick Fix: Use a liquid seam sealant like “Fray Check.” It works, but be warned—it makes the edge feel hard and crunchy.

- The Pro Fix: Physical stitching is always better than glue. If you have a vintage scarf that is unraveling, a pin hem (a tiny, tight fold) is the best way to save it.

Final Thoughts: Should You DIY or Outsource?

Learning how to make a silk scarf is a rewarding skill. There is nothing quite like finishing that hem yourself.

But here is the reality check: If you are a designer planning to sell these, do you really want to spend 45 minutes hand-rolling every single piece?

If you are looking for custom made scarf production with perfect hand-rolled edges (without the finger cramps), we are here to help. At Bysporting, we turn your silk scarf pattern into retail-ready products.

[Click here to upload your design and let us handle the hard work.]

1. How much does a real silk scarf cost?

Real silk scarves range from $20 for basics to over $400 for luxury brands with hand-rolled edges.

2. How is a silk scarf made?

The process involves weaving raw silk, digital printing, steaming to lock color, washing, and hemming the edges.

3. How to sew silk for beginners?

Use a fine Microtex needle and place tissue paper under the fabric to stop it from slipping while you sew.

4. What size should a silk scarf be?

Standard sizes are 53cm squares for bandanas, 90cm for classic squares, and 50x180cm for long scarves.