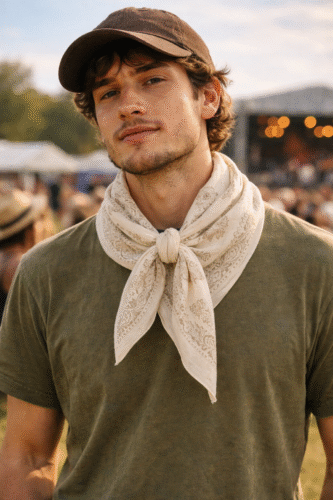

Bandanas are arguably the most versatile accessory in your wardrobe. From a stylish neck scarf and a functional hair tie to a necessary dust mask or a cute pet accessory, this simple square of fabric does it all.

If you search online for Cómo hacer un pañuelo, you will find countless tutorials. But as a professional bandana manufacturer (at Bysport.com) who produces tens of thousands of units for global brands and events every year, I want to share a different perspective.

We know that the difference between a “craft project” and a “retail-quality product” comes down to three things: Fabric Density (GSM), Precision Sizing, and the Hemming Technique.

Based on our factory production standards, here is your ultimate guide to making a bandana the professional way.

Tabla de contenido

PalancaStep 1: Choosing the Best Fabric for Bandanas

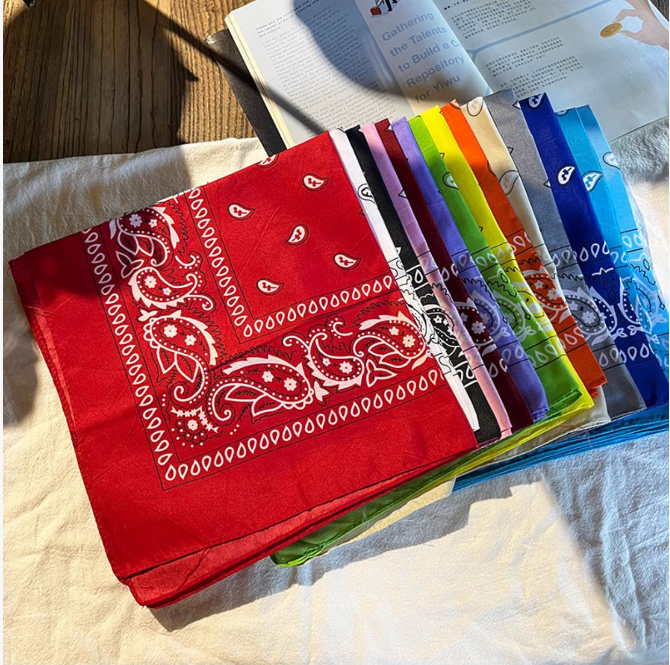

The fabric you choose determines 70% of the final quality. You can’t just grab any scrap of cloth. In our factory, we select fabrics based on how they drape, breathe, and hold a knot.

1. 100% Cotton (The Industry Standard)

Best for: Daily wear, outdoor activities, and pets.

For a classic feel that gets softer with every wash, 100% Cotton is the best choice.

- Consejo profesional: Look for “Cotton Poplin” or premium “Quilting Cotton.”

- The Golden Rule: We recommend a weight of 110–130 GSM. Anything lighter feels cheap and transparent; anything heavier will be too thick to tie comfortably around your neck.

2. Polyester Microfiber (Best for Performance)

Best for: Sports, cycling, and complex logo printing.

If you see seamless tube bandanas or vibrant full-color event bandanas, they are likely Polyester Microfiber. It is moisture-wicking, quick-drying, and wrinkle-resistant.

3. Silk or Satin (The Luxury Choice)

Best for: Fashion head scarves and sleeping wraps.

Silk offers an elegant shine and protects hair from frizz. However, be warned: silk is slippery and requires advanced sewing skills (specifically a rolled hem).

Step 2: The Standard Bandana Size Chart

One of the most common questions we receive is: “What size should I cut?”

A generic square isn’t precise enough. To get a professional finish, you must account for the seam allowance (the extra fabric folded over the edge).

Here are the exact cutting dimensions used in professional manufacturing:

| User / Use Case | Finished Size (After Sewing) | Cut Size (Fabric Needed) |

| Standard Adult | 22″ x 22″ (55cm) | 23″ x 23″ |

| Oversized / Kerchief | 27″ x 27″ (70cm) | 28″ x 28″ |

| Child / Pocket Square | 18″ x 18″ (45cm) | 19″ x 19″ |

| Large Dog | 20″ x 20″ (50cm) | 21″ x 21″ |

| Small Pet / Cat | 14″ x 14″ (35cm) | 15″ x 15″ |

Manufacturer’s Note: The “Cut Size” includes a 0.5-inch allowance on all sides for a double-fold hem.

Step 3: Tools You Will Need

To achieve a clean, square result, you need the right setup:

- Fabric (Pre-washed to prevent shrinking!)

- Rotary Cutter & Mat (Scissors work, but rotary cutters ensure perfectly straight lines)

- Iron & Ironing Board (Non-negotiable for crisp edges)

- Sewing Machine

- Thread (Matching color)

Step 4: Cutting and Hemming (The Step-by-Step)

1. Cut on the Grain

This is a detail often skipped by hobbyists but strictly followed in factories. You must cut your square parallel to the “grainline” (the direction of the threads). If you cut “off-grain,” your bandana will twist and warp permanently after the first wash.

2. The “Double Fold” Hem (Durability Method)

Raw edges will fray immediately. To get a professional finish without an industrial serger machine, use the double-fold method:

- First Fold: Place fabric wrong-side up. Fold the edge over by approx. 1/4 inch. Press with your iron.

- Second Fold: Fold over again by another 1/4 inch to hide the raw edge completely. Press again.

- The Corners: Before sewing, trim a tiny triangle of fabric off the corner tip to reduce bulk.

- Stitch: Sew a straight line down the center of your folded hem.

3. The “Rolled Hem” (For Silk & Luxury)

If you are making a bufanda de seda personalizada, a bulky double fold looks bad. High-end brands use a Rolled Hem.

- Technique: This requires a specific “rolled hem foot” on your machine, or meticulous hand-sewing. It creates a tiny, delicate edge that allows the fabric to drape naturally.

Conclusion: DIY vs. Custom Manufacturing

Congratulations! You now know Cómo hacer un pañuelo that is durable, washable, and perfectly sized. Sewing a few unique pieces for yourself or as gifts is a rewarding project.

However, is DIY the right choice for your business?

If you are planning an event, launching a brand, or need uniform gear for a team, sewing 50 or 100 bandanas by hand is incredibly time-consuming and difficult to keep consistent.

That is where we come in.

As a dedicated manufacturer, Bysport helps you scale from a DIY idea to a professional product line. We offer:

- Custom Bandanas with Logo (High-Definition Digital or Screen Print).

- Precision Laser Cutting (For perfectly straight, non-fraying edges).

- Industrial Hemming (Baby lock, rolled hem, or standard stitching).

- Low MOQ & Fast Delivery.

Whether you choose to craft it yourself or partner with us for a bulk order, we hope this guide helps you create the perfect headwear!

FAQ: Frequently Asked Questions

Q: What is the best fabric for a bandana?

A: For general use, 100% Cotton Poplin (approx 120gsm) is the industry standard. It is breathable, soft, and holds a knot well. For sports, Polyester Microfiber is preferred for its sweat-wicking properties.

Q: How much fabric do I need for one bandana?

A: For a standard adult bandana, you need a square of 23 inches by 23 inches. If you are buying fabric by the yard (usually 44″ wide), 2/3 of a yard can typically yield two bandanas.

Q: Can I print my own logo on a bandana at home?

A: You can use iron-on transfers or fabric stamps for DIY projects. However, for durable, full-color designs that don’t peel off, professional dye sublimation or screen printing is recommended.