(A Factory Guide for Bulk Buyers)

Author: Bysport Manufacturing Team | Category: Manufacturing Guides | Read Time: 6 Minutes

Introduction

When you design a benutzerdefinierte Bandana, most people focus almost entirely on the artwork and pattern. However, based on 10+ years of real manufacturing experience at Bysport, we have seen thousands of orders succeed—or fail—because of a detail many buyers overlook: the Bandana Edge finish.

Choosing the wrong edge finish can make a luxury silk scarf look cheap, or turn a budget promotional bandana into an unnecessarily expensive product. This guide is written to solve a real problem buyers face every day:

“Which bandana edge finish actually fits my use case, budget, and expectations?”

As a direct factory specializing in bulk bandana manufacturing, we will objectively compare the three Bandana Edge industry-standards—Laser Cut, Merrowing (Overlock), and Hemming—so you can make a confident, informed decision.

1. Laser Cut Edge: Speed, Precision, and Cost Control

If you are sourcing Polyester-Bandanas, seamless neck gaiters, or need fast turnaround for large events, the Laser Cut Edge is often the most practical solution.

What Is Laser Cutting?

Instead of thread and needle, high-precision laser machines cut the fabric directly.1 The heat from the laser instantly seals (cauterizes) the edge of synthetic fabrics, preventing fraying without any stitching.2

Why Buyers Choose Laser Cut:

- Cost Efficiency: No thread, no sewing labor. This makes it the lowest-cost edge finish for bulk wholesale orders.

- Perfect Dimensions: Laser cutting prevents fabric distortion, ensuring consistent 55×55cm sizing—a common requirement for events.

- Comfort: The edge is flat and soft, ideal for tubular neck gaiters or sports bandanas where seams may cause skin irritation.

⚠️ Factory Warning: Laser cutting works best on polyester or synthetic blends. It is not recommended for 100% cotton bandanas, as cotton fibers burn/char instead of sealing cleanly.

Real Use Case: Marathon events, music festivals, large-scale promotional giveaways.

2. Merrowing (Overlock Stitch): The Durable, Retail-Ready Standard

If you have ever bought a classic cotton bandana, chances are it used Merrowing, also known as an overlock stitch. This is the most widely used edge finish in the retail market.

What Is Merrowing?

(Caption: Merrowing creates a durable border, perfect for retail and outdoor use.)

A specialized sewing machine wraps thread tightly around the raw fabric edge, creating a visible, reinforced border that locks fibers in place.

Why Buyers Choose Merrowing:

- Durability: Designed to withstand frequent washing and daily use. Ideal for custom dog bandanas, outdoor gear, and workwear.

- Material Versatility: Works perfectly on 100% cotton, polyester, rayon, and blends.

- Perceived Value: It costs slightly more than laser cutting but creates a “finished” retail look that customers associate with quality.

💡 Design Tip: Der thread color can be customized. Many streetwear brands intentionally choose contrasting merrow stitching (e.g., Neon Green thread on Black fabric) to enhance visual identity.

Real Use Case: Retail streetwear, pet accessories, outdoor lifestyle brands.

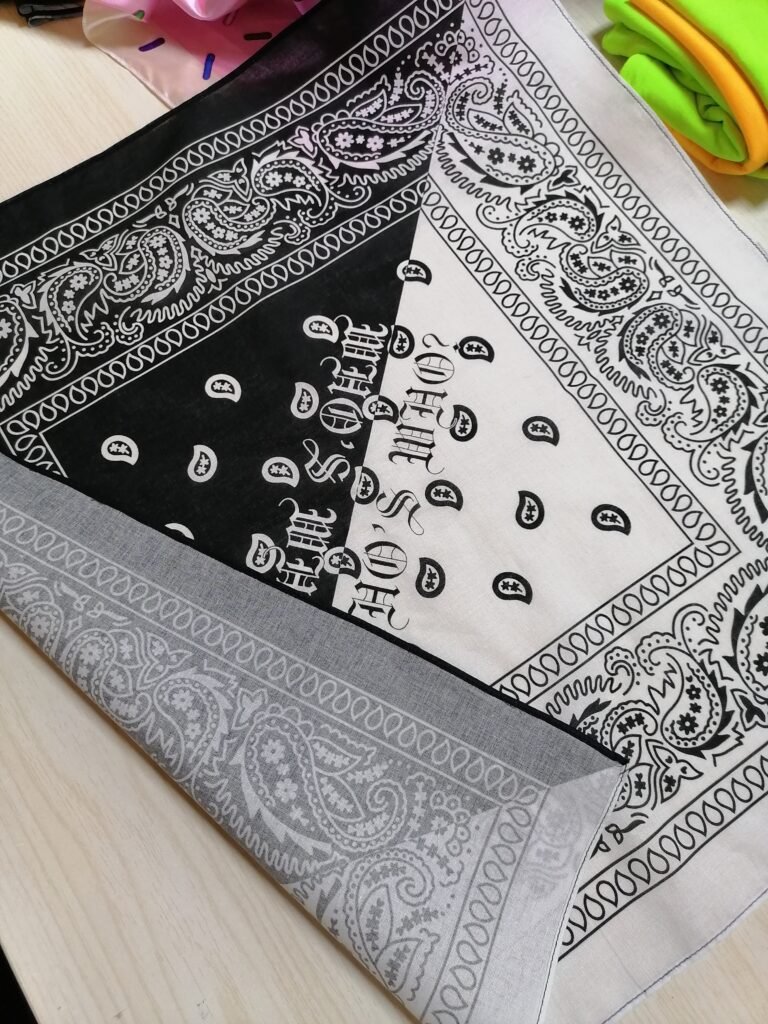

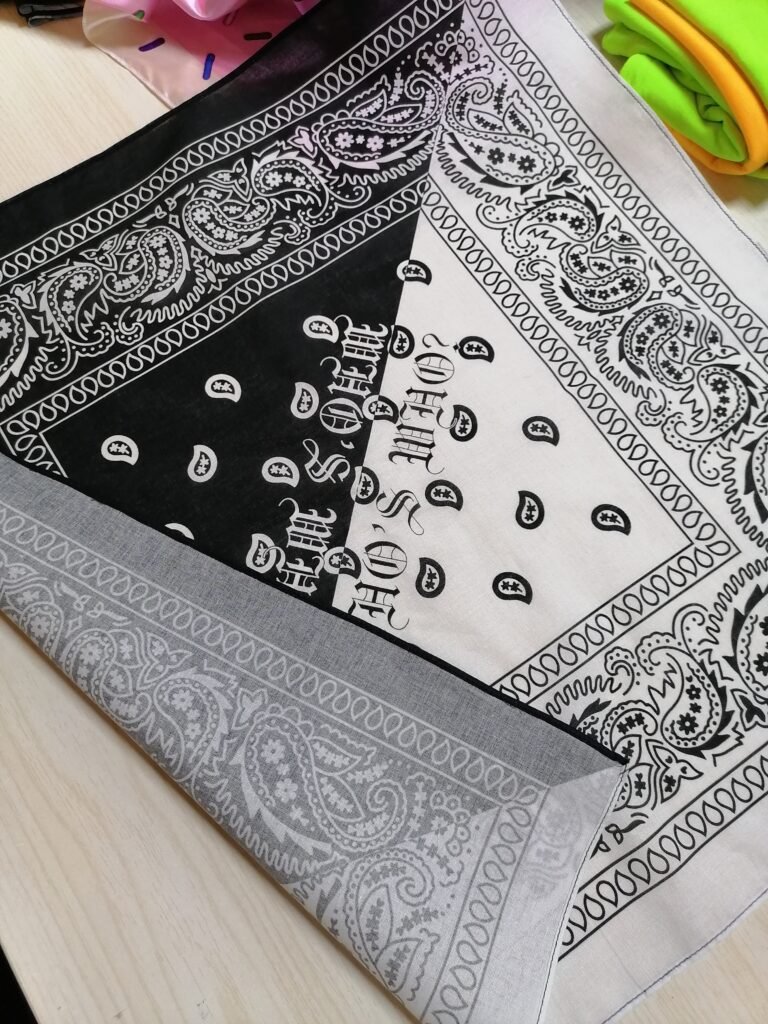

3. Hemming (Pin Hem / Rolled Edge): The Premium Choice

If you are producing fashion bandanas, corporate gifts, or Seidenschals, Merrowing often looks too “industrial.” This is where Hemming becomes essential.

(Caption: The clean, folded edge of a Baby Hem elevates the product to a fashion accessory.)

What Is Hemming?

The fabric edge is folded inward and stitched, hiding raw edges completely.

- Baby Hem (Machine Rolled): A clean, narrow finish commonly used for high-end cotton or silk-blend scarves.

- Hand-Rolled Edge: Fully hand-finished and reserved for 100% silk luxury scarves.

Why Buyers Choose Hemming:

- Higher Perceived Value: Instantly elevates the product into a high-end fashion accessory.

- Clean Aesthetics: Minimal stitching allows your custom logo and artwork to extend closer to the edge without a thick border distraction.

Real Use Case: Boutique brands, premium corporate gifts, luxury silk scarves.

Quick Comparison Table: Which Edge Fits Your Project?

| Besonderheit | Laser Cut | Merrowing (Overlock) | Hemming (Baby Hem) |

| Best Material | Polyester, Microfiber | Cotton, Polyester, Blends | Silk, Cotton, Rayon |

| Production Speed | Very Fast | Medium | Slow |

| Unit Cost | $ (Lowest) | $$ (Medium) | $$$ (High) |

| Haltbarkeit | Good | Excellent | Delicate to Good |

| Am besten für | Events, Promotions | Retail, Pets, Outdoor | Fashion, Gifts |

Real Buyer Case Studies

Case A: City Marathon Event (Cost & Comfort Focus)

- Challenge: A client needed 10,000 pieces for a run with a tight budget and fast delivery.

- Solution: We recommended Laser Cut Polyester Bandanas.

- Result: 30% cost savings vs. sewn edges, zero skin irritation complaints, and delivered on time.

Case B: Vintage Streetwear Brand (Quality Focus)

- Challenge: A brand selling $25 USD retail bandanas wanted an authentic, heavy feel.

- Solution: We used Merrowing on vintage-wash cotton fabric with matching thread.

- Result: The durable finish garnered consistent 5-star reviews for quality.

Final Advice: Choose Based on Use, Not Hype

There is no single “best” edge finish—only the right choice for your specific project:

- Need speed and the lowest price? → Go Laser Cut.

- Need durability and retail acceptance? → Go Merrowing.

- Need premium presentation and gifting value? → Go Hemming.

As a BSCI-certified manufacturer, Bysport handles all three processes in-house. We don’t just print; we advise.

Still not sure which one to pick?

Don’t guess. [Contact Us to Request a Sample Kit].

Feel the difference between Laser Cut, Merrowed, and Hemmed edges with your own hands before you commit to a bulk order.