(A Factory Guide for Bulk Buyers)

Author: Bysport Manufacturing Team | Category: Manufacturing Guides | Read Time: 6 Minutes

Zavedení

When you design a zakázkový šátek, most people focus almost entirely on the artwork and pattern. However, based on 10+ years of real manufacturing experience at Bysport, we have seen thousands of orders succeed—or fail—because of a detail many buyers overlook: the Bandana Edge finish.

Choosing the wrong edge finish can make a luxury silk scarf look cheap, or turn a budget promotional bandana into an unnecessarily expensive product. This guide is written to solve a real problem buyers face every day:

“Which bandana edge finish actually fits my use case, budget, and expectations?”

As a direct factory specializing in bulk bandana manufacturing, we will objectively compare the three Bandana Edge industry-standards—Laser Cut, Merrowing (Overlock), and Hemming—so you can make a confident, informed decision.

1. Laser Cut Edge: Speed, Precision, and Cost Control

If you are sourcing polyesterové šátky, seamless neck gaiters, or need fast turnaround for large events, the Laser Cut Edge is often the most practical solution.

What Is Laser Cutting?

Instead of thread and needle, high-precision laser machines cut the fabric directly.1 The heat from the laser instantly seals (cauterizes) the edge of synthetic fabrics, preventing fraying without any stitching.2

Why Buyers Choose Laser Cut:

- Cost Efficiency: No thread, no sewing labor. This makes it the lowest-cost edge finish for bulk wholesale orders.

- Perfect Dimensions: Laser cutting prevents fabric distortion, ensuring consistent 55×55cm sizing—a common requirement for events.

- Comfort: The edge is flat and soft, ideal for tubular neck gaiters or sports bandanas where seams may cause skin irritation.

⚠️ Factory Warning: Laser cutting works best on polyester or synthetic blends. It is not recommended for 100% cotton bandanas, as cotton fibers burn/char instead of sealing cleanly.

Real Use Case: Marathon events, music festivals, large-scale promotional giveaways.

2. Merrowing (Overlock Stitch): The Durable, Retail-Ready Standard

If you have ever bought a classic cotton bandana, chances are it used Merrowing, also known as an overlock stitch. This is the most widely used edge finish in the retail market.

What Is Merrowing?

(Caption: Merrowing creates a durable border, perfect for retail and outdoor use.)

A specialized sewing machine wraps thread tightly around the raw fabric edge, creating a visible, reinforced border that locks fibers in place.

Why Buyers Choose Merrowing:

- Durability: Designed to withstand frequent washing and daily use. Ideal for custom dog bandanas, outdoor gear, and workwear.

- Material Versatility: Works perfectly on 100% cotton, polyester, rayon, and blends.

- Perceived Value: It costs slightly more than laser cutting but creates a “finished” retail look that customers associate with quality.

💡 Design Tip: Ten/Ta/To thread color can be customized. Many streetwear brands intentionally choose contrasting merrow stitching (e.g., Neon Green thread on Black fabric) to enhance visual identity.

Real Use Case: Retail streetwear, pet accessories, outdoor lifestyle brands.

3. Hemming (Pin Hem / Rolled Edge): The Premium Choice

If you are producing fashion bandanas, corporate gifts, or hedvábné šátky, Merrowing often looks too “industrial.” This is where Hemming becomes essential.

(Caption: The clean, folded edge of a Baby Hem elevates the product to a fashion accessory.)

What Is Hemming?

The fabric edge is folded inward and stitched, hiding raw edges completely.

- Baby Hem (Machine Rolled): A clean, narrow finish commonly used for high-end cotton or silk-blend scarves.

- Hand-Rolled Edge: Fully hand-finished and reserved for 100% silk luxury scarves.

Why Buyers Choose Hemming:

- Higher Perceived Value: Instantly elevates the product into a high-end fashion accessory.

- Clean Aesthetics: Minimal stitching allows your custom logo and artwork to extend closer to the edge without a thick border distraction.

Real Use Case: Boutique brands, premium corporate gifts, luxury silk scarves.

Quick Comparison Table: Which Edge Fits Your Project?

| Funkce | Laser Cut | Merrowing (Overlock) | Hemming (Baby Hem) |

| Best Material | Polyester, Microfiber | Cotton, Polyester, Blends | Silk, Cotton, Rayon |

| Production Speed | Very Fast | Medium | Slow |

| Unit Cost | $ (Lowest) | $$ (Medium) | $$$ (High) |

| Trvanlivost | Good | Excellent | Delicate to Good |

| Nejlepší pro | Events, Promotions | Retail, Pets, Outdoor | Fashion, Gifts |

Real Buyer Case Studies

Case A: City Marathon Event (Cost & Comfort Focus)

- Challenge: A client needed 10,000 pieces for a run with a tight budget and fast delivery.

- Solution: We recommended Laser Cut Polyester Bandanas.

- Result: 30% cost savings vs. sewn edges, zero skin irritation complaints, and delivered on time.

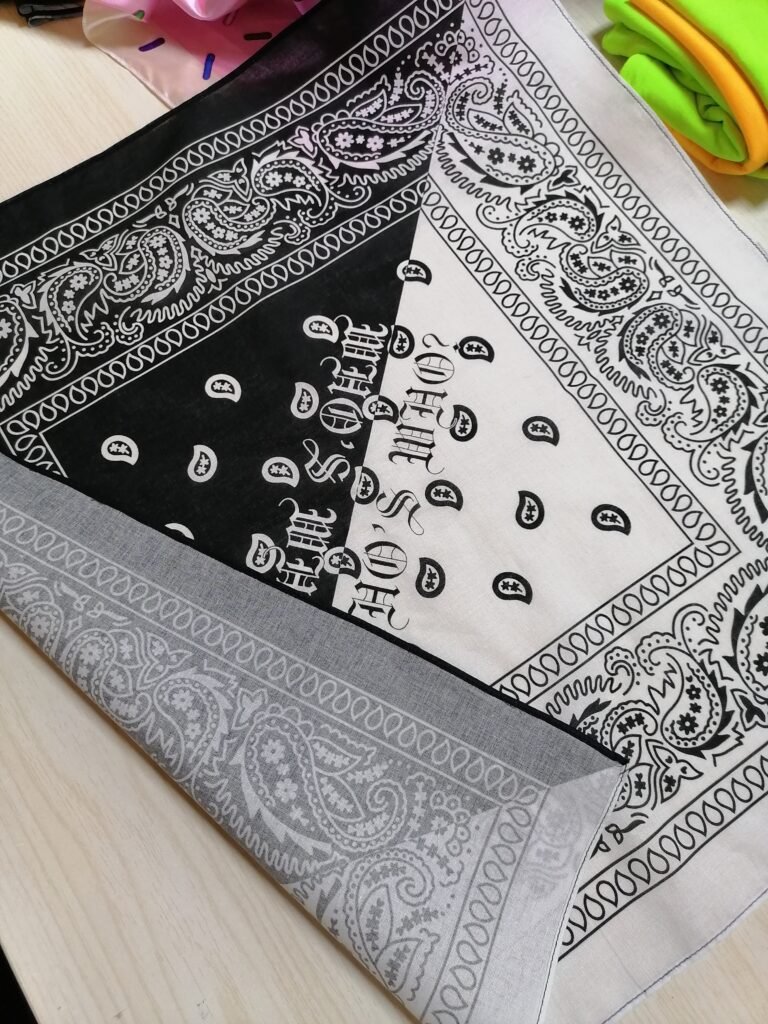

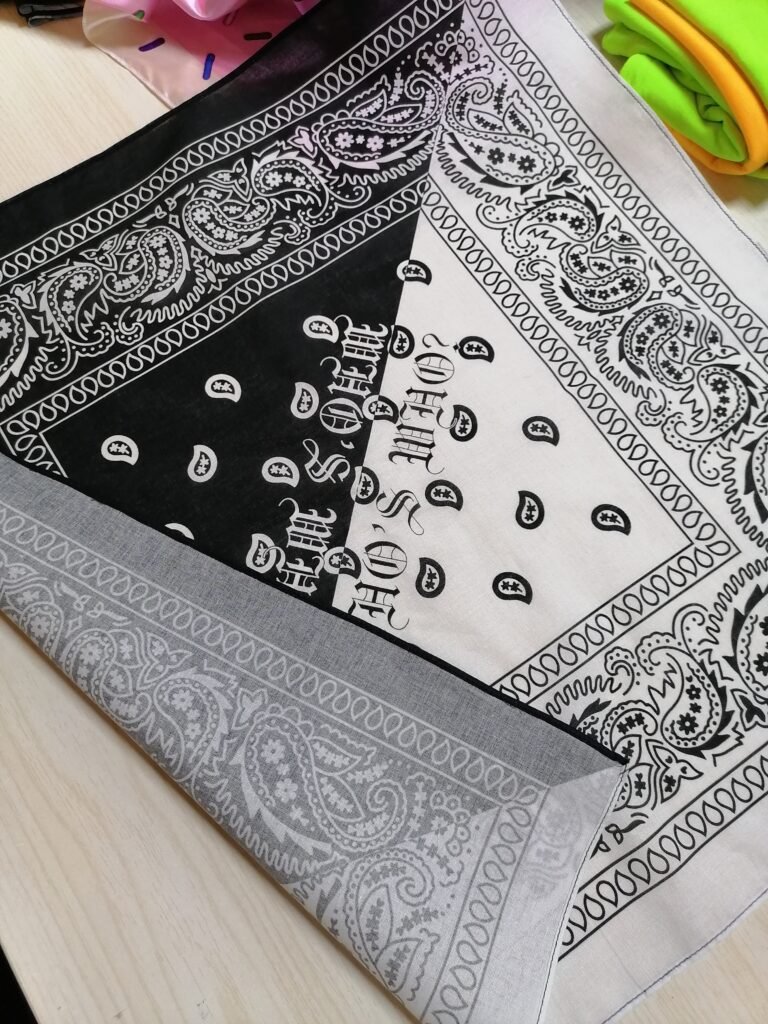

Case B: Vintage Streetwear Brand (Quality Focus)

- Challenge: A brand selling $25 USD retail bandanas wanted an authentic, heavy feel.

- Solution: We used Merrowing on vintage-wash cotton fabric with matching thread.

- Result: The durable finish garnered consistent 5-star reviews for quality.

Final Advice: Choose Based on Use, Not Hype

There is no single “best” edge finish—only the right choice for your specific project:

- Need speed and the lowest price? → Go Laser Cut.

- Need durability and retail acceptance? → Go Merrowing.

- Need premium presentation and gifting value? → Go Hemming.

As a BSCI-certified manufacturer, Bysport handles all three processes in-house. We don’t just print; we advise.

Still not sure which one to pick?

Don’t guess. [Contact Us to Request a Sample Kit].

Feel the difference between Laser Cut, Merrowed, and Hemmed edges with your own hands before you commit to a bulk order.