By Bysport Manufacturing Team | Updated December 2025

As a professional buyer or brand owner, sourcing custom bandanas usually comes down to one critical crossroads: which printing method should you choose for your project.

At the Bysport factory, we hear this question every day. You already have a design in hand, but you are not sure what is the difference between screen printing and digital printing when it comes to real-world bulk production. If the wrong method is selected, the result may be a stiff bandana that is uncomfortable to wear on the face, or an unexpectedly high unit cost caused by unnecessary setup fees.

This guide is not theoretical. It is based on our direct experience manufacturing millions of bandanas for global brands. In the following sections, we will clearly compare digital printing vs screen printing quality, digital printing vs screen printing cost, and long-term durability, so you can make a confident and profitable sourcing decision.

جدول المحتويات

تبديلThe 30-Second Decision Matrix

If you do not have time to read the entire article, this is the same “cheat sheet” our Bysport sales engineers use when advising buyers.

| ميزة | Digital Printing (Direct-to-Fabric) | Screen Printing (Silk Screen) |

| الأفضل لـ | Complex artwork, photos, gradients, small batches | Simple logos, solid colors, large bulk orders |

| MOQ (Minimum Order) | Low (often under 100 pcs) | Higher (recommended 500–1000+ pcs) |

| Setup Cost | Low or none | High (screen fee per color) |

| Color Limit | Unlimited ∞ | Usually max 8–12 colors |

| Hand Feel | No ink feel, very soft | Noticeable ink layer |

| Fabric Penetration | Medium, lighter on the back | High, visible on both sides |

This table alone answers most questions about screen printing vs digital printing for bandana sourcing.

1. Deep Dive: What Is Digital Printing?

Digital printing can be compared to an office inkjet printer, but on a massive industrial scale. In textile manufacturing, we use an advanced digital screen printing machine, typically Direct-to-Fabric or Sublimation equipment, which injects ink directly into the fabric fibers.

When buyers ask about digital printing vs screen printing quality, digital printing clearly stands out in terms of detail. It can accurately reproduce photographic images, complex illustrations, fine mandala lines, and smooth tie-dye gradients that are not achievable with traditional screens.

Another key advantage is comfort. Because the ink bonds with the fibers rather than sitting on top, the finished bandana remains soft, breathable, and suitable for face wear such as neck gaiters. At Bysport, our digital production lines can also switch between designs within seconds, making digital printing ideal for fast turnaround and flexible production.

2. Deep Dive: What Is Screen Printing?

Screen printing is a traditional and well-proven technique. For each color in a design, a physical mesh stencil is created, and ink is pushed through the screen onto the fabric. When comparing digital vs silk screen printing, screen printing can be understood as layering solid ink colors onto the textile surface.

Buyers choose this method for several strong reasons. First, spot colors matched to Pantone standards appear extremely vibrant and consistent across large production runs. Second, in terms of bandana-specific performance, screen printing vs digital printing offers superior backside penetration. Because more ink is physically pushed into the fabric, the design remains clearly visible on both sides, which is important for double-sided wear.

Once the screens are produced, screen printing becomes very fast and economical, especially for large-volume orders.

3. Cost Analysis: Finding Your Break-Even Point

For most buyers, cost is the deciding factor. In practice, digital printing vs screen printing cost depends almost entirely on order quantity and the number of colors used in the design.

Screen printing involves a setup fee for every color. For example, a six-color design may require approximately USD 200 in screen fees before production even begins. Digital printing, by contrast, has little to no setup cost.

As a result, orders under 500 pieces are typically more economical with digital printing, while orders above 2,000 pieces strongly favor screen printing because the setup cost is spread across a much larger quantity. The 500–1000 piece range is a grey zone, where design complexity becomes the deciding factor, and this is where factory-side calculation is most valuable.

4. Durability & Quality: The Factory Perspective

A common concern is durability, particularly when buyers compare digital printing vs screen printing durability.

Screen printing produces a thick ink layer that is extremely resistant to washing, although poorly cured plastisol inks can crack over time. Digital printing using sublimation or reactive inks is also highly durable. Because the ink becomes part of the fiber, it does not crack or peel, although slight fading may occur after extensive washing.

From a finishing perspective, Bysport integrates laser cutting into production. Digital printing allows us to add invisible positioning marks, enabling precise laser cutting and consistent square edges. Screen-printed fabrics may stretch slightly during printing, which can make ultra-precise cutting more challenging.

5. Real-World Case Studies

To better understand the difference between screen print and digital print, the following real orders from our factory illustrate typical use cases.

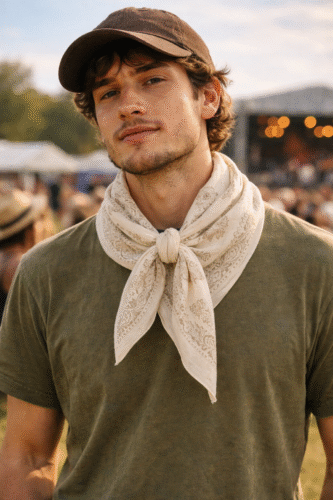

Case A: Music Festival Bandanas (Digital Printing)

- Challenge: A festival vendor required a 20-color galaxy design with smooth gradients.

- Solution: Screen printing was not suitable due to color limitations. Digital sublimation reproduced every detail accurately and maintained a soft hand feel.

- Result: High retail value due to intricate design quality.

Case B: Supermarket Promotion Bandanas (Screen Printing)

- Challenge: A national retail chain ordered 50,000 bandanas featuring a two-color paisley design.

- Solution: Screen printing delivered exact Pantone color matching and an extremely low unit cost.

- Result: Screen printing vs digital printing examples like this prove that traditional methods are unbeatable for high-volume ROI.

6. Screen Printing vs Heat Press

Buyers sometimes ask about screen printing vs heat press. Heat press methods apply vinyl or transfer films to fabric, similar to ironing on a sticker.

For bulk bandana manufacturing, we do not recommend heat press. The result is a heavy, non-breathable patch that cracks over time and reduces comfort. Professional production should rely on either digital screen printing (DTF/DTG) or traditional screen printing.

Conclusion: Which Method Should You Choose?

Understanding what is the difference between screen printing and digital printing is the foundation of a successful bandana project.

- Choose Digital If: You want soft, breathable fabrics, complex artwork, small to medium quantities (<1,000 pcs), or fast samples.

- Choose Screen If: You have a simple design, need exact Pantone matching, and are ordering in bulk (2,000+ pcs) where cost efficiency matters most.

If you are still unsure, Bysport operates both advanced digital screen printing machine lines and high-capacity screen printing facilities.

[CTA Button] Get a Free Cost Analysis

Upload your design file, and our engineering team will calculate the exact price difference for your specific order.

التعليمات

Q: What is the difference between screen printing and digital printing durability?

A: Both methods are suitable for retail-quality bandanas. طباعة الشاشة offers strong wash resistance, while digital printing never cracks and provides better comfort for face wear.

Q: Can you show screen printing vs digital printing examples?

A: Yes. Our product gallery includes high-resolution images comparing texture, color saturation, and backside penetration.

Q: Is digital printing vs screen printing cost always higher?

A: No. Digital printing is often cheaper for small orders (under 500 pcs) or designs with many colors, because you save on screen setup fees.

Q: What is digital screen printing?

A: The term usually refers to Direct-to-Fabric or DTG processes where ink is applied digitally without physical screens, combining the speed of digital with the quality of traditional printing.